China is mobile phone production base in the world. With the huge terminal market demand, the shift of mobile phone supply chain to Chinese mainland has become an industry trend. Under the background of 5G development and the Sino-US trade war, the localization process of RF filter, as an important component of RF front-end, needs to be accelerated. RF filters are the development focus of RF device localization. The lack of filters in mobile phones means that the communication equipment loses anti-interference abilities and can not guarantee smooth communication.

As a rising domestic RF front-end device enterprise in recent years, Hangzhou Sappland Microelectronics Technology Co., Ltd. (referred to as “Sappland Microelectronics”) recently disclosed that the key technology of the temperature compensated surface acoustic wave (TC-SAW) filter developed by the company has made a breakthrough, and the relevant products are ready for mass production. The launch of this product means an important breakthrough for domestic filters, which will fill the market gap of high-end RF filters in China and break the monopoly situation of foreign manufacturers in this field.

TC-SAW for 5G band needs to break the monopoly of foreign market

The main implementation methods of RF filters in mobile phones are SAW and BAW. BAW has better performance and is suitable for more medium and high frequency segments, but the process is complex and the price is higher than that of SAW. However, the conventional SAW filter on the market can not be well applied to the frequency band above 2GHz: when the frequency is higher than about 1GHz, its selectivity is reduced. In the frequency band of about 2.5GHz, it is limited to the application with low performance requirements, and the working frequency of the filter fluctuates with the change of the external temperature. Because of these characteristics, the conventional SAW can not meet the requirements of RF terminals for filters in the 5G era. It is necessary to develop filters with high frequency and temperature stability.

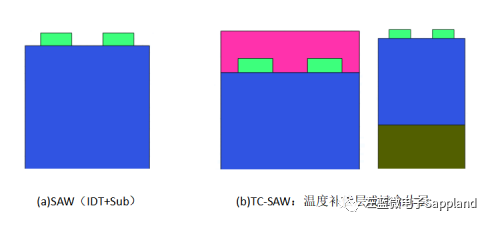

Temperature compensated SAW (TC-SAW for short) improves the performance of conventional SAW filters by coating or bonding temperature a compensation layer (as shown in Figure 2: structure comparison between conventional SAW and TC-SAW), so that the frequency temperature coefficient (TCF) of the device is reduced to 0 to – 25ppm / °C. Compared with conventional SAW, the temperature characteristic (usually about – 45 – 60ppm / °C) has been significantly improved.

Because the temperature compensation process needs double mask layer, the device structure is more complex, and the manufacturing cost is higher than that of conventional SAW filter, but it is still significantly lower than that of BAW filter. The comparative advantages of performance and cost make TC- SAW filters usher in a good development opportunity in 5G era. TC-SAW can be widely used in mobile terminal, base station, satellite communication, smart home, car radar, RFID, radar system and other wireless terminals.

The RF front-end chip market has always been dominated by overseas oligarchs, and TC-SAW products are mainly monopolized by Japanese manufacturers. In contrast, domestic RF chip companies, due to their delayed start and weaker foundation, still lags behind international leading enterprises in technology accumulation, industrial environment, talent training and innovation ability, possessing a large gap with European and American manufacturers. Presently, domestic manufacturers mainly produce low-end SAW. For TC-SAW and BAW with higher technical requirements, only a few domestic manufacturers are in the stage of technical research, especially the core technology of TC-SAW. The Chinese market urgently needs to implement localized supply and services.

Sappland Microelectronics TC-SAW technology fills gap of domestic products

Since 2016, Sappland microelectronics has been arranging RF front-end devices, especially filters. The TC-SAW filter developed by Sappland team has successfully passed the verification of relevant key technical points, solved the problems of poor temperature characteristics and serious frequency drifts of conventional SAW filters, and filled the technical gap of TC- SAW in China. The company aspires to lay a solid industrial foundation for the development of 5G communication in China.

TC SAW has two types of process methods: a temperature compensation layer method and a bonding plate method. Generally used as the base of temperature compensation layer method, SiO2 is used as temperature compensation layer, and the working mode is Rayleigh wave (i.e. longitudinal wave and vertical shear wave or l-sv waves). The advantage is that the mechanical and electrical coupling coefficient is large, while the disadvantage is the complex design and process: the bonding plate method is generally lt+si substrate. The working mode is SH waves (as shown in Fig. 3) with the temperature coefficient smaller than that of conventional SAW. The electrical performance is similar to that of conventional SAW. The advantages are that the design and technology can refer to conventional SAW, which is relatively simple, but the electromechanical coupling coefficient is smaller than that of temperature compensation layer method.

Sappland Microelectronics has mastered the complete TC-SAW design technology and a complete set of independent process design schemes. Through the precise modal analysis and design from resonator to filter, the temperature performance of the filter can be greatly improved. For the sound meter device, the structure parameters of the filter are optimized quickly by the self-developed design tool to achieve the high performance filter.

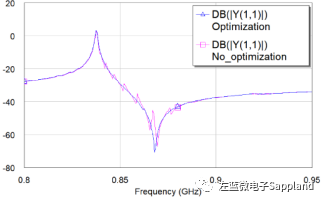

Furthermore, the harmonic can be effectively suppressed by the optimized resonator design. Figure 4 shows the optimal design effect of resonator:

By optimizing the design, the harmonic is suppressed and the Q value of the resonator is effectively improved. The Q value of a resonator is as follows: qs=1269, qp=1467, qmax=1765. The results are shown in Figure 5:

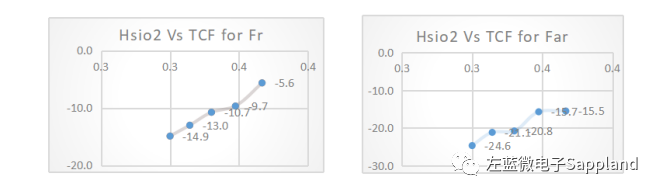

The influence of the thickness of surface temperature compensation layers on TCF can be effectively simulated, and the specific implementation way of process optimization is proposed. Through the combination of design simulation and process optimization, the TC-SAW filter with the best TCF can be prepared, as shown in Figure 6:

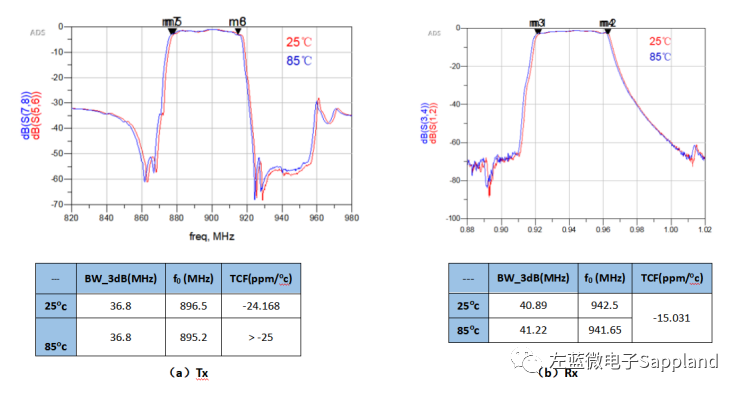

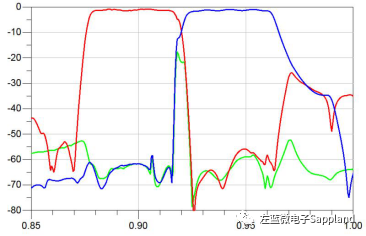

The TC-SAW filter obtained by accurate simulation has excellent performance at high and low temperatures. Currently, the TC-SAW products independently developed by Sappland have been continuously optimized, and the optimal TCF has reached – 15ppm / 0C (as shown in Figure 7). Compared with traditional devices, it has achieved the advantages of small size, low insertion loss and high operating frequency (0.5Ghz-3ghz). The performance curve of the designed duplexer isshown in Figure 8, which is comparable to the international first-class level.

Under the background of f China’s wireless broadband strategy implementation and the rapid development of wireless communication terminals, the successful R & D and mass production of Sappland Microelectronics TC-SAW series products will provide multi-mode and multi frequency support for 5G communication. Such 5G communication is conducive to the large-scale development of domestic high-quality and low- cost multi-mode and multi frequency mobile terminals. At present, the product has completed performance verification in platforms such as Qualcomm, MTK and Spreadtrum. The large-scale production of domestic TC-SAW also has a great role in promoting the development of RF component providers, terminal equipment providers, design manufacturers, and business operators in the industrial chain. Sappland will continue to improve the level of industrial technology and the independent control ability of high-end filters, promoting the upgrading of industrial structure.